ALTA 2019

Conference Report

ALTA 2019 was a fantastic week! It was another big week including 100 presentations, 3 short courses, 3 social events and the exhibition. Enjoy the conference report and photos below. See you all next year at ALTA 2020, our 25th anniversary event.

All Opening and Keynote presentations or papers are available from the ALTA Free Library. In addition, for the first time, recordings of opening and keynote addresses are also available from Conference Videos. The proceedings and panel discussion notes will be published by end July.

ALTA 2019 was the largest conference in its 24-year history, with record attendance of 450 delegates from 32 countries, reflecting 20% growth on 2018. We were excited to welcome 250 new faces, along with previous attendees and ALTA regulars for this world-class annual metallurgical event.

ALTA 2019 was the largest conference in its 24-year history, with record attendance of 450 delegates from 32 countries, reflecting 20% growth on 2018. We were excited to welcome 250 new faces, along with previous attendees and ALTA regulars for this world-class annual metallurgical event.

We thank each of our opening speakers, keynote speakers, presenters, session chairs, exhibitors, sponsors, co-sponsors, partners, delegates and student volunteers for their important contribution to the success of the event.

The event was opened by Conference Founder and Chair, Alan Taylor, Managing Director and Metallurgical Consultant, ALTA Metallurgical Services.

We value the support of our 29 sponsors, partners, co-sponsors and media partners, some have been with us for many years. We would like to thank MEI for publishing a daily blog of the event: Monday, Tuesday, Conference Dinner, Wednesday, Thursday, Friday.

We value the support of our 29 sponsors, partners, co-sponsors and media partners, some have been with us for many years. We would like to thank MEI for publishing a daily blog of the event: Monday, Tuesday, Conference Dinner, Wednesday, Thursday, Friday.

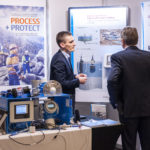

Our largest exhibition to date included 42 exhibitors and was attended by 75 visitors in addition to conference attendees.

Conversation was flowing during lunch breaks, and the Welcome Reception and Happy Hour networking functions.

Alan Taylor’s Dinner Address “The Rise of Cobalt - A Laterite Wars Story” was informative and entertaining, and well received by 155 dinner guests. Security was provided by several Star Wars “stormtroopers” assisted by guests armed with lightsabers (see photos).

The conference commenced with the Opening Address by David Weight, President, Cobalt Institute (UK), presenting “The Changing Landscape of the Cobalt Market”.

The conference commenced with the Opening Address by David Weight, President, Cobalt Institute (UK), presenting “The Changing Landscape of the Cobalt Market”.

The presentation reviewed the historical changes to the cobalt market, noting specifically the impact that cobalt containing Li‑ion battery development has had, while looking at the challenges that cobalt faces in the global market place, from chemical management to responsible sourcing, and the role that cobalt plays in the development of the circular economy.

All Opening and Keynote presentations or papers will be available from the ALTA Free Library. In addition, for the first time, videos of opening and keynote addresses will also be published.

The Nickel-Cobalt-Copper Sessions kicked-off with the Keynote Address by Dr Bryn Harris, Managing Partner, NMR360 Inc (Canada): “The Future of Ni-Co-Cu Processing in the Age of Lithium-Ion Batteries”.

The Nickel-Cobalt-Copper Sessions kicked-off with the Keynote Address by Dr Bryn Harris, Managing Partner, NMR360 Inc (Canada): “The Future of Ni-Co-Cu Processing in the Age of Lithium-Ion Batteries”.

The presentation briefly reviewed the many flowsheets for cobalt production due to its complex chemistry, including the recent industry focus on HPAL for the treatment of laterites which have experienced cost, ramp-up time and equipment problems. He also pointed out the potential of chloride-based technology which have been successfully used for nickel and cobalt. He discussed historical and current developments in batteries and proposed that technology will change to eliminate cobalt but not for Ev batteries, and that recycling of batteries will become mandatory and can be developed relatively quickly. He estimates cobalt production will meet demand till about 2025, beyond that depends on how quickly new capacity can brought on stream.

Feature presentations included Dr Stephen Grocott, Clean TeQ (Australia) on “The Clean TeQ Sunrise Project – A one Stop from Nickel Laterites to Lithium Ion Battery Feedstock – Project Update”, and Mike Hourn, Glencore Technology (Australia) on “First Commercialisation of the Albion ProcessTM for Copper”.

Feature presentations included Dr Stephen Grocott, Clean TeQ (Australia) on “The Clean TeQ Sunrise Project – A one Stop from Nickel Laterites to Lithium Ion Battery Feedstock – Project Update”, and Mike Hourn, Glencore Technology (Australia) on “First Commercialisation of the Albion ProcessTM for Copper”.

Prof Jacques Eksteen, Research Director at FBICRC (Australia) presented on “The Future Battery Industries Co-operative Research Centre (FBICRC) and its Role to Catalyse Growth in Industries Across the Battery Value Train”.

Session topics included battery metals; laterite processing, including scandium production; project risk; extraction and purification, filtration, leaching process development, heap leaching, and included a Pressure Acid Leaching Forum.

Project presentations included an update of the Platina scandium from laterite HPAL project, NSW. Australia; uranium recovery from cobalt leach solution for a cobalt plant in DRC; assessing hydrometallurgical recovery of cobalt at Teck’s zinc refinery, Canada; review of Anaconda, and former Bulong and Cawse HPAL projects in Australia; CIX pilot plant operation and implication of rheology for the Clean TeQ Nickel-Cobalt-Scandium project, Australia; and heap bioleaching in Boreal conditions at Terrafame’s polymetallic operation, Finland.

Project presentations included an update of the Platina scandium from laterite HPAL project, NSW. Australia; uranium recovery from cobalt leach solution for a cobalt plant in DRC; assessing hydrometallurgical recovery of cobalt at Teck’s zinc refinery, Canada; review of Anaconda, and former Bulong and Cawse HPAL projects in Australia; CIX pilot plant operation and implication of rheology for the Clean TeQ Nickel-Cobalt-Scandium project, Australia; and heap bioleaching in Boreal conditions at Terrafame’s polymetallic operation, Finland.

The Pressure Acid Leaching Panel was chaired by Alan Taylor and acknowledged the 20-year anniversary of the commissioning of the Bulong, Cawse and Murrin PAL projects.

The Pressure Acid Leaching Panel was chaired by Alan Taylor and acknowledged the 20-year anniversary of the commissioning of the Bulong, Cawse and Murrin PAL projects.

Topics discussed and debated by the panel and delegates, included improvements to current PAL concept, indirect preheaters, single stage vertical autoclaves, co-treatment of laterites and sulphides, PAL discharge acid utilisation or recycle, MHP vs MSP vs CIX/SX for producing nickel and cobalt sulphates, PAL vs NPI for producing nickel and cobalt sulphates, lower cost alternatives to PAL, e.g. AL, HL, nitric leach or chloride leach.

Panel discussion notes will be published in the coming weeks.

The Gold-PM Sessions, organised in partnership with the Curtin Gold Technology Group, commenced with the Keynote Address by Prof Jacques Eksteen, Director, Gold Technology Group and Chair, Extractive Metallurgy, Western Australian School of Mines, Curtin University (Australia) on “Fit-for-Purpose Precious Metals Leach Systems: Matching Leach Strategies to Source Characteristics”.

The Gold-PM Sessions, organised in partnership with the Curtin Gold Technology Group, commenced with the Keynote Address by Prof Jacques Eksteen, Director, Gold Technology Group and Chair, Extractive Metallurgy, Western Australian School of Mines, Curtin University (Australia) on “Fit-for-Purpose Precious Metals Leach Systems: Matching Leach Strategies to Source Characteristics”.

The thrust of the presentation was that the focus should be on establishing the optimum leaching system to fit the contexts of geology and mineralogy, natural and geographic setting, engineering and economics, materials, reagents and products, preconcentration and upstream processing. In most cases, cyanide will be the answer, however there are cases where regulations, ore characteristics, mining strategy (in-situ, in-mine), site considerations, process chemistry, or economics are drivers for considering alternative lixiviants. At present, there is no established panacea, and alternatives should be subjected to rigorous investigation and risk assessment within the overall contexts of the operation.

Session topics included the application of IX for cyanide recycling and gold recovery from carbon fines; process optimisation including evaluation of oxygen usage for refractory concentrates, impeller development for tank bioleaching, field scale demonstration of a new thiosulphate leaching process, optimal monitoring and operation of carbon circuits, and real-time analysis of gold in plant slurries; and a Fit-for-Purpose Leaching Systems Forum including geometallurgy and process mineralogy, cyanide free processing simulation and modelling, technology options for varying refractory ores, mixed chloride process development, minimising impact of copper in EW and gravity processing, and glycine-cyanide process development for gold-copper ores.

Session topics included the application of IX for cyanide recycling and gold recovery from carbon fines; process optimisation including evaluation of oxygen usage for refractory concentrates, impeller development for tank bioleaching, field scale demonstration of a new thiosulphate leaching process, optimal monitoring and operation of carbon circuits, and real-time analysis of gold in plant slurries; and a Fit-for-Purpose Leaching Systems Forum including geometallurgy and process mineralogy, cyanide free processing simulation and modelling, technology options for varying refractory ores, mixed chloride process development, minimising impact of copper in EW and gravity processing, and glycine-cyanide process development for gold-copper ores.

The Fit-for Purpose Leaching Systems Panel was chaired by Prof Jacques Eksteen

The Fit-for Purpose Leaching Systems Panel was chaired by Prof Jacques Eksteen

Topics addressed included obtaining a greater uptake of alternative lixiviants in mining companies; increasing the use of IX in gold plant processing; identification of hybrid lixiviant systems to extend the range (pH-Eh-T-Ionic strength) of applicability; what can replace CIP/CIL?; what can be considered to replace interstage screen; thiosulfate leaching for heap and ISL leaching?; options to perform cyanide-free glycine leaching at room temperature in agitated tank CIP/CIL circuits with a maximum 48 hr residence time; and the future of halide leaching in treating low grade gold ores.

Panel discussion notes will be published in the coming weeks.

The Uranium-REE Sessions, organised in cooperation with the International Atomic Energy Agency (IAEA), were opened by Dr Brett Moldovan, Team Leader, Uranium Resources and Production, IAEA (Austria) with a presentation on “What will Future Uranium Mining Projects Look Like?”.

The Uranium-REE Sessions, organised in cooperation with the International Atomic Energy Agency (IAEA), were opened by Dr Brett Moldovan, Team Leader, Uranium Resources and Production, IAEA (Austria) with a presentation on “What will Future Uranium Mining Projects Look Like?”.

The presentation concluded that lower grade deposits will dominate future global resources and will be sandstone and unconformity types. Geology, mineralogy and geochemistry will guide future mine and process flowsheet design which will be dominated by ISR. Innovation opportunities to reduce costs include application of ISL to unconformity type deposits, stope (block) leaching, physical and chemical preconcentration, advances in heap leaching for low grade ores, and innovation in full life cycle issues, such as mine closure.

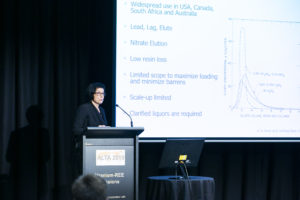

Dr Karin Soldenhoff, Technology Manager - Minerals, ANSTO (Australia) followed with the Uranium Keynote Address: “Uranium IX - Past, Present and Future”.

Dr Karin Soldenhoff, Technology Manager - Minerals, ANSTO (Australia) followed with the Uranium Keynote Address: “Uranium IX - Past, Present and Future”.

The presentation briefly reviewed resin chemistry, early IX fixed bed processes, and still relevant past innovations including improved resins, CIX and RIP systems for unclarified solutions and slurries, the Eluex/Bufflex IX/SX system for dilute solutions, and U-tube elution. Recent and future innovations include IX/nanofiltration (NF) for reagent recycle in elution, SX/IX to reduce reagent costs when using strong acid SX strip, IX to remove impurities from NF feed to prevent fouling and scaling, IX/IX using different resins for by-product uranium recovery from phosphoric acid, resins for saline leach solutions, and novel elution systems to reduce opex.

Session topics were heap leaching including development of a geometallurgical uranium leaching predictive tool for the Olympic Dam operation, progress review of the Central Jordan Uranium Project, and the research of cladding for radon exhalation control for acidic uranium heap leaching tailings in China; review of Dubbo Rare Metal and REE and Nolans NdPr project developments; by-product uranium recovery from phosphates and copper concentrates; process developments for REE extraction and fluid bed precipitation of uranium oxide concentrates; and a Developments in IX Forum including developments in selective resins for REE and actinides and the positioning of IX in the uranium industry.

Session topics were heap leaching including development of a geometallurgical uranium leaching predictive tool for the Olympic Dam operation, progress review of the Central Jordan Uranium Project, and the research of cladding for radon exhalation control for acidic uranium heap leaching tailings in China; review of Dubbo Rare Metal and REE and Nolans NdPr project developments; by-product uranium recovery from phosphates and copper concentrates; process developments for REE extraction and fluid bed precipitation of uranium oxide concentrates; and a Developments in IX Forum including developments in selective resins for REE and actinides and the positioning of IX in the uranium industry.

The Uranium IX Panel was chaired by Alan Taylor.

The Uranium IX Panel was chaired by Alan Taylor.

Topics discussed and debated included current resin developments, future wish list for IX in uranium and REE processing, developing new resins versus Impregnation with SX extractants, IX versus SX for chloride solutions and recovering uranium from phosphoric acid, development in IX systems and whether uranium from sea water has a future.

A summary of the panel discussion will be published in the coming weeks.

The Lithium Processing Sessions were opened by a Keynote Address by Adrian Griffin, Managing Director, Lithium Australia (Australia) discussing “Innovation Required to Meet Future Lithium Demand”.

The Lithium Processing Sessions were opened by a Keynote Address by Adrian Griffin, Managing Director, Lithium Australia (Australia) discussing “Innovation Required to Meet Future Lithium Demand”.

The presentation identified better resource utilisation, effective recycling and innovations in battery chemistry as key solutions to the sustainable and ethical supply of lithium. For hard-rock sources, this involves exploiting different styles of mineralisation such as greisens, clays and waste discharge streams containing lithium micas. For brines, yield can be improved via chemical processes that recover lithium more efficiently than evaporation ponds. Lithium can be recycled using hydrometallurgical rather than pyrometallurgical techniques that discharge much of the lithium to slag or flue gas. Battery innovations to reduce demand for lithium and other battery metals include improving anode performance, designing for longer life and adoption of lithium iron phosphate which uses only half of the Li, no Co.

Session topics were advances in battery production and recycling; roasting and calcination including tunnel kiln mineral roasting, and nature of physical properties in selection of calcination and roasting equipment; project development including project derisking through metallurgical testing and piloting, prediction of brine chemistry and properties in salar evaporation, and cost effective use of duplex stainless steel in production plants; safety in lithium mining and processing; purification and recovery including the use of selective resins and membrane technology; and a Novel Lithium Processes Forum including production from spodumene, processing of clay, and lithium carbonate and hydroxide production processes.

Session topics were advances in battery production and recycling; roasting and calcination including tunnel kiln mineral roasting, and nature of physical properties in selection of calcination and roasting equipment; project development including project derisking through metallurgical testing and piloting, prediction of brine chemistry and properties in salar evaporation, and cost effective use of duplex stainless steel in production plants; safety in lithium mining and processing; purification and recovery including the use of selective resins and membrane technology; and a Novel Lithium Processes Forum including production from spodumene, processing of clay, and lithium carbonate and hydroxide production processes.

The Novel Lithium Processes Panel discussion was chaired by Dr Chris Griffith, Senior Process Chemist / Business Development Lead, ANSTO Minerals (Australia).

The Novel Lithium Processes Panel discussion was chaired by Dr Chris Griffith, Senior Process Chemist / Business Development Lead, ANSTO Minerals (Australia).

The agenda included the ‘real’ price of running first to production of LiOH in W.A.; de-risking processing of ‘non-conventional’ lithium resources; impact of innovative technology developments including Li selective extractants / adsorbants, alternative flowsheets, and trace impurity removal (high purity concentrate production); and opportunities for alternative LIB precursor feed chemicals including avoiding LiOH - is it possible?

A summary of the panel discussion will be published in the coming weeks.

The parallel In Situ Recovery Sessions, organised in partnership with CSIRO, were kicked-off with a Keynote Address by Dr Horst Maerten, Vice President Technology, Heathgate Resources (Australia) and CEO, UIT (Germany): “Trends in ISR Technology”

The parallel In Situ Recovery Sessions, organised in partnership with CSIRO, were kicked-off with a Keynote Address by Dr Horst Maerten, Vice President Technology, Heathgate Resources (Australia) and CEO, UIT (Germany): “Trends in ISR Technology”

He highlighted that after a 60-year history, largely for uranium recovery, the development of ISR technology is in its 4th stage - the feasibility of recovering other metals. Challenges include systematising the feasibility criteria, characterising wellfield hydrology and leaching chemistry, and generically describing the dependence of project economics on key variables. By referring to recent advancements in Uranium ISR, the key areas of project development and application include exploration/delineation methodology and 3D deposit modelling, innovative test procedures and scale-up to field conditions, wellfield design/optimisation/control, metal processing including bioleaching, and aquifer restoration.

Session topics were developments in uranium ISR including automated ground water monitoring, and reactive transport simulation of well clogging; use of bacteria including where does microbially assisted ISR make sense?, and use of bugs for monetising stranded assets; ISR for non-uranium metals including overview of existing applications, Kapunda copper ISR project, staged acid leaching of bornite, methodology for assessing amenability of copper and gold ores, and leaching of gold in microchannels with alkaline glycine; and an Enhancing ISR Permeability Forum including innovations in rock fragmentation and fracturing, potential use of blasting, fracture stimulation using non-explosive demolition agents, hydraulic fracturing of hard rock; and methods and equipment for hydraulic fracturing field trials.

Session topics were developments in uranium ISR including automated ground water monitoring, and reactive transport simulation of well clogging; use of bacteria including where does microbially assisted ISR make sense?, and use of bugs for monetising stranded assets; ISR for non-uranium metals including overview of existing applications, Kapunda copper ISR project, staged acid leaching of bornite, methodology for assessing amenability of copper and gold ores, and leaching of gold in microchannels with alkaline glycine; and an Enhancing ISR Permeability Forum including innovations in rock fragmentation and fracturing, potential use of blasting, fracture stimulation using non-explosive demolition agents, hydraulic fracturing of hard rock; and methods and equipment for hydraulic fracturing field trials.

The Enhancing ISR Permeability Panel was chaired by Dr Laura Kuhar, Research Team Leader, CSIRO (Australia).

The Enhancing ISR Permeability Panel was chaired by Dr Laura Kuhar, Research Team Leader, CSIRO (Australia).

Topics discussed and debated included: application of hydraulic fracturing to gold and copper ores, use of slurry pumping to generate hard rock fractures, risks due to public and government concerns about fracking, application of ISR to stranded ore deposits, application of in-ground “silo” leaching, and whether higher recoveries could be achieved by using a small-scale test to predict the effect of blasting on achievable recovery.

The conference was enhanced by three practically oriented technical short courses presented by Alan Taylor. “Treatment of Nickel-Cobalt Laterites”, “Copper SX/EW Basic Principles and Detailed Plant Design” and Heap Leaching & its Application to Copper, Gold, Uranium & Nickel Ores”. The SX Fire Protection section of the SX/EW course was presented by Larry Moore, FM Global (USA).

The conference was enhanced by three practically oriented technical short courses presented by Alan Taylor. “Treatment of Nickel-Cobalt Laterites”, “Copper SX/EW Basic Principles and Detailed Plant Design” and Heap Leaching & its Application to Copper, Gold, Uranium & Nickel Ores”. The SX Fire Protection section of the SX/EW course was presented by Larry Moore, FM Global (USA).

The three weekend courses were extremely popular, recording our highest attendance with 74 people from 20 Countries. Attendees included both senior experienced professionals and newcomers seeking an introduction to the various topics.

ALTA short course manuals, seven in total, are available for purchase and immediate download from Publications. All short course manuals are kept current with annual updates.

Conference photographs are available from ALTA 2019.

Conference photographs are available from ALTA 2019.

Opening and Keynote presentations or papers will be available from the ALTA Free Library.

In addition, for the first time, videos of the seven opening and keynote presentations will be published on our website. Notes from all panel discussions will also be published.

ALTA 2019 conference proceedings will be available for purchase and download from Publications by end July.

Click to enlarge images. Images may be downloaded for use with credit to ALTA 2019 (#ALTA2019) and link to the conference page.

Conference Sessions

Exhibition and Networking

Conference Dinner

- Now receiving abstracts for ALTA 2020, our 25th anniversary event. Presenters receive 50% discount on registration fees. 75% discount for sole consultant presenters.

- The conference will feature forums and panels on Hydromet Processing of Ni-Co-Cu Sulphides, Application of Membranes in Uranium Processing, Cyanide Alleviation and Alternative Lixiviants, Application of ISR to Copper and Innovations in Lithium Processing.

- Three short courses are scheduled: A-Z of Copper Ore Leaching, SX and its Application to Copper, Uranium & Nickel-Cobalt, and Uranium Ore Processing.

- Get in early to stake your claim on your preferred booth or sponsorship. Contact Allison Taylor